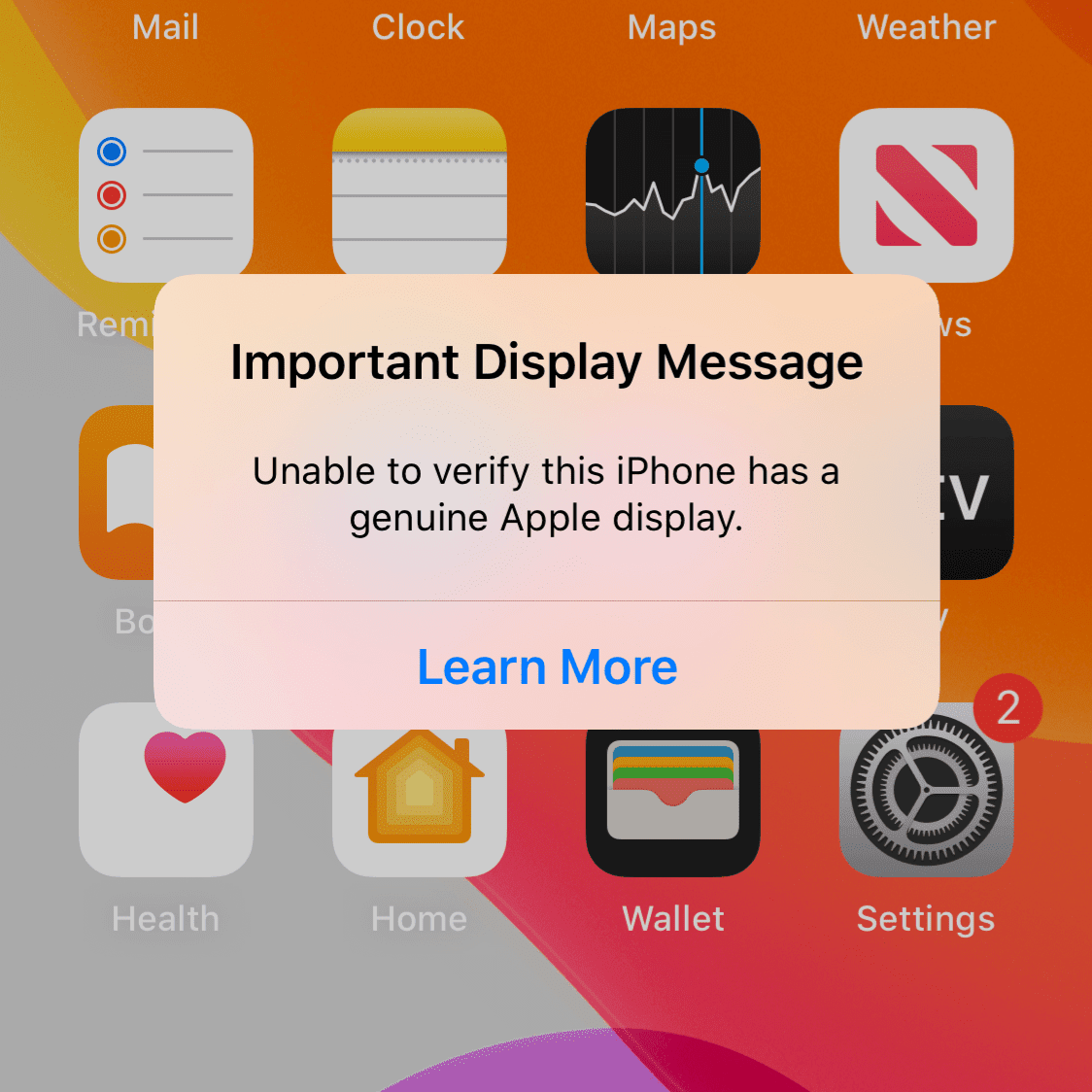

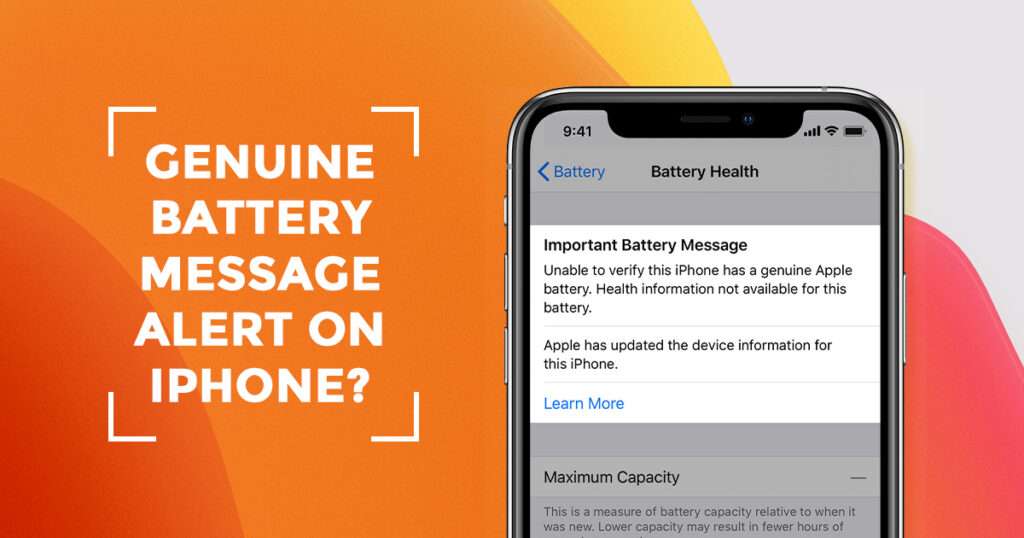

After third-party display repairs, an Important Display Message appearing on Home Screen has nothing to do with the replacement screen, whether it’s an aftermarket screen or an OEM screen.

iPhone system couldn’t verify the touch module data during start-up after new screen replacement and you will get a popup message on your screen. Touch module of the original screen has a unique ID which is binded with the iPhone System. And this touch Module is located on screen and replacing screen results in a mismatch of the information stored in touch module of the replacement screen and the iPhone System.

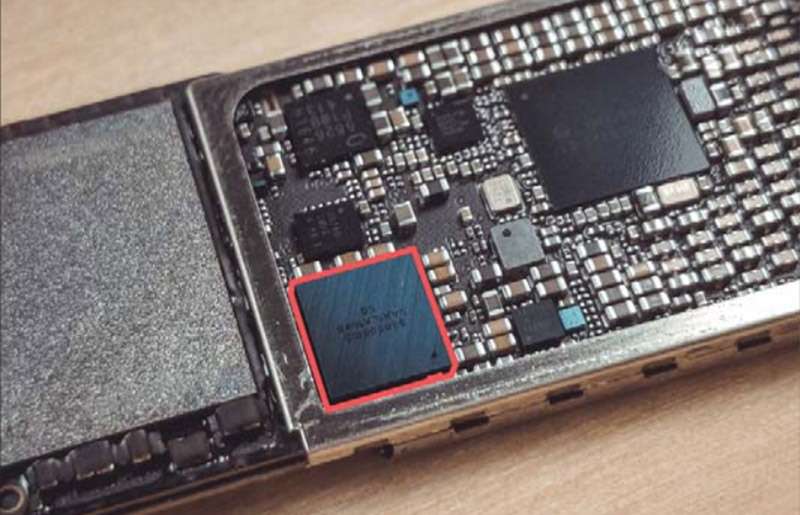

We can fix this problem which only requires special soldering skills. We have to transfer the Touch Module of Original screen onto the new replacement screen. We can not use traditional soldering tools for this repair. We need a special grinding tool for this repair.

.

How to Fix this issue?

Steps:-

- 1. Tick high-temperature tape around the touch module on the replacement screen. Then wrap the screen with protective film.

- 2. Now we will grind the touch module with the electric chip grinding tool.

- Be patient during the grinding. Start with the top layer then move on to the next layer. Also, be careful not to damage flex cables nearby.

- With solder joints coming out, stop the grinding work. Clean the bonding pad with PCB Cleaner soaked cotton swap afterwards.

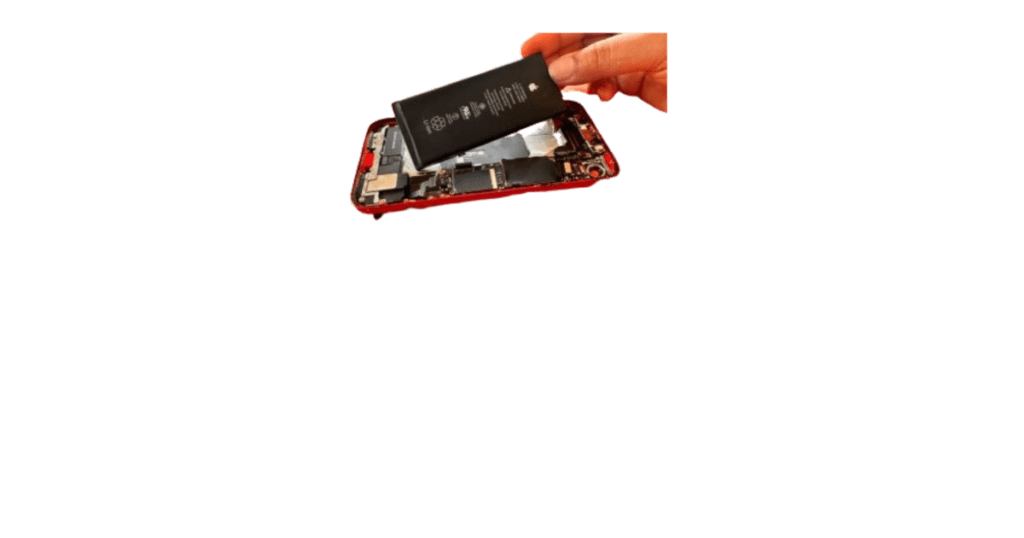

- 3. Now we need to remove the touch module on the original screen and solder it onto the new replacement screen.

- 4. To remove touch module on your iPhone screen, start by taking off the earpiece speaker and sensor flex cable from the initial screen. Next, slide a sheet of paper underneath the touch flex cable. Use a Hot Air Gun to warm up the screen and carefully lift the touch module on the original screen.

- After that, use low-temperature solder paste to coat the touch module. Apply heat using a Soldering Iron at 365℃ to remove any leftover solder paste and black adhesive. Use Solder Wick to clean any remaining debris, and then use PCB Cleaner to thoroughly clean the area.

- Next, proceed with reballing the touch module. Finally, you need to solder the touch module (which has been reballed) onto the new screen.

- Before starting the soldering process, carefully insert a pry piece under the touch flex cable. To facilitate the process, a small amount of alcohol can be applied to this area. The metal plate and paper are used to provide heat insulation, preventing the screen from being damaged by high temperatures during soldering.

- Apply a small amount of paste flux to the bonding pad, and position the touch module correctly. Finally, use a Hot Air Gun to solder the components together.